TECSEP SOLUTIONS

WELLBORE CLEAN OUT SERVICES

A comprehensive suite of specialized tools and filtration equipment that deliver a clean wellbore ready for the completion process.

Casing cleaning tools is an integral component for the wellbore drilling fluids displacement, and removal of downhole debris. The mud film thickness deposited inside the internal surfaces of the well casings or tubular require a dedicated mechanical and chemical cleaning trip.

The cleaning solution involves the speciality tools with fit for purpose design of the string, serving as a drift run, combined with the chemical technology, this proves an efficient sequence to maximise the wellbore assurance ,in preparation for completions on production or injection wells.

Best practice includes running wellbore cleanout tools to scrape packer setting depths and mechanically remove debris that have the potential to damage the completion hardware. Fluid properties should be maintained during this trip to assist with wellbore cleanout and remove any other solids in the well.

TECSEP specially selected clean out tools removes the drilling fluid solids and cement in one trip. The pill train chemistry carefully selected removes the oil-based mud residue and water-wet´s the tubulars in just over one circulation, as well as specialized software which models the hydraulics to size the tools requirements and spacers, ensuring a unique and effective cleaning whilst maximizing productivity. Our experienced personnel will be able to support your operations with planning, logistics and safety playing a key role in the process.

TECSEP SOLUTIONS

WELLBORE CLEAN OUT SERVICES FULL RANGE

BOP AND RISER SERVICES

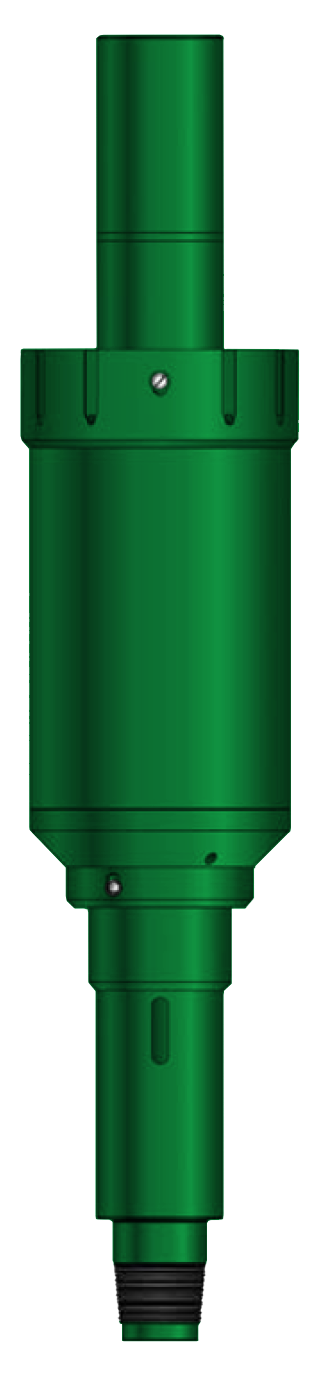

BOP JETTING TOOL

TECSEP’s BOP jetting Tool cleans debris from BOP ram cavities by creating a fluid vortex. Compared to conventional jetting tools that can unintentionally force debris into the ram cavities, this tool pulls debris out of the ram cavities and away from the BOP via the fluid vortex.

The design of this tool eliminates the risk of damaging the BOP annular preventer element and enables a higher flow rate.

CLEAN DEBRIS FROM BOP

APPLICATIONS

- Jetting subsea blowout preventers (BOPs)

PULL DEBRIS OUT OF THE RAM CAVITIES

FEATURES AND BENEFITS

- Unique jetting profile creates a vortex that pulls debris away from BOP ram cavities

- Jet flow profile eliminates the risk of damaging the BOP annular preventer element

- Higher flow rate compared to conventional jetting tools Tool Description

BOP AND RISER SERVICES

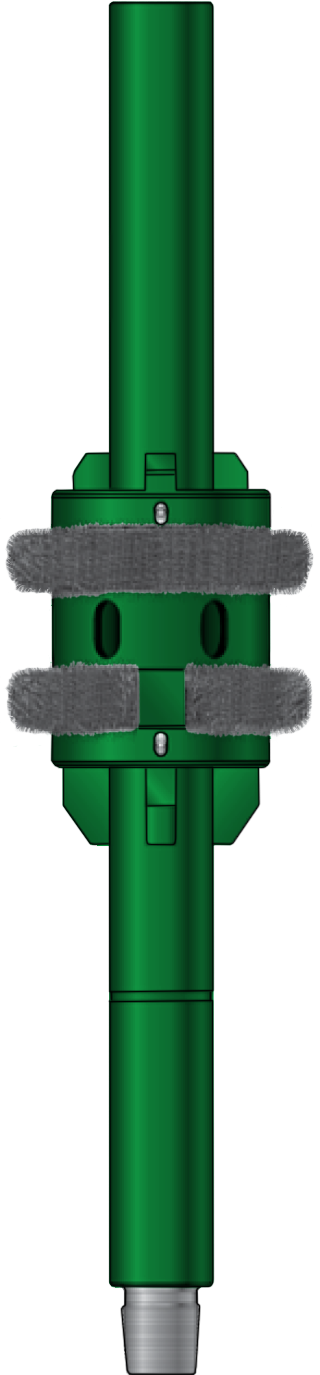

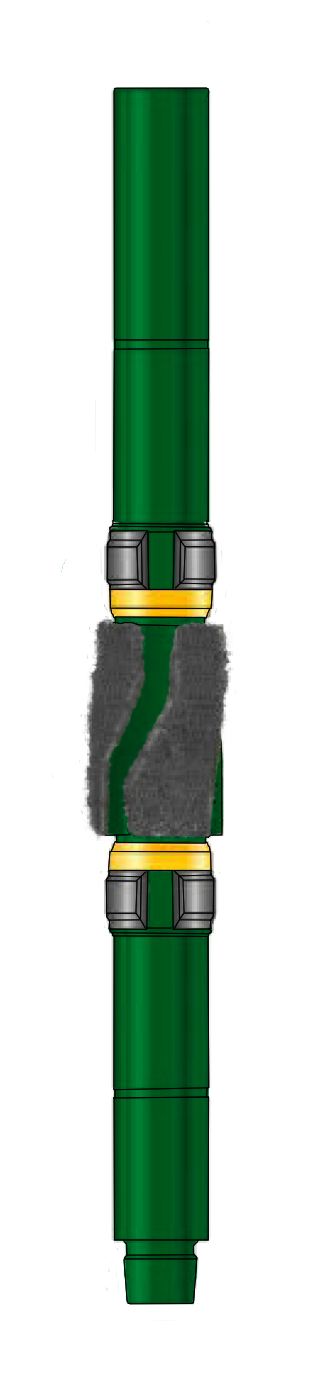

RISER BRUSH TOOL

TECSEP’s Riser Brush Tool is a simple, robust tool for cleaning heavy debris and mud cake build up from the internal diameter of the marine riser.

The large bypass and proven brush design provide a reliable method of preparing the riser for displacement operations.

ROBUST TOOL FOR CLEANING HEAVY DEBRIS APPLICATIONS

APPLICATIONS

- Run in clean-up string to remove solids from the internal diameter (ID) of the marine riser

PROVIDE REALIABLE METHODS OF PREPARING THE RISER

FEATURES AND BENEFITS

- 360º brush coverage across the ID of the riser cleans the whole riser

- The large bypass under the brush elements enables maximum flow rates

- The nonrotating brushes minimize wear on brushes and the riser ID

- Robust, wire-wrapped and welded bristles create tough reliable brushes

- The tool is easy to size for any riser ID

BOP AND RISER SERVICES

TRAP TOOL

TECSEP’s Trap Tool is a riser junk basket for use in marine-riser and BOP clean-up operations. Generally positioned above the Riser Brush Tool, the Trap junk basket collects any debris falling out of circulation as a result of reduced annular velocities in large ID marine risers.

COLLECTS ANY DEBRIS FALLING OUT OF CIRCULATION

APPLICATIONS

- Marine riser cleaning operations

RELIABLE TOOL FOR MARINE RISING CLEANING

FEATURES AND BENEFITS

- The large capacity basket features a retaining screen in the base for enhanced debris collection

- The trap junk basket works in conjunction with the line of blowout preventers (BOPs) and marine riser clean up tools

- Large volumes of debris can be collected in the catchment chamber, which helps to prevent miss runs during completion operations

CASING CLEANING SERVICES

BRUSH TOOL

TECSEP’s Brush Tool is a robustly designed casing brush that will scour and polish the casing ID. Because of its tough design and large flow area, the Brush Tool thoroughly prepares the casing ID for low-tolerance HPHT packers and workover operations. Each tool model covers a range of casing sizes.

SCOUR AND POLISH THE CASING ID

APPLICATIONS

- Casing and tubing cleaning operations

- Polishing of production-packer set points

THOROUGHLY PREPARES THE CASING ID

FEATURES AND BENEFITS

- Rotational design reduces the chance of brush and casing wear

- 360º brush coverage of the casing ID, regardless of the well inclination

- Large flow area between the exterior of the tool and the casing ID, which reduces equivalent circulating density and guards against surge

- Integral centralizers maintain constant positive force on the casing ID

CASING CLEANING SERVICES

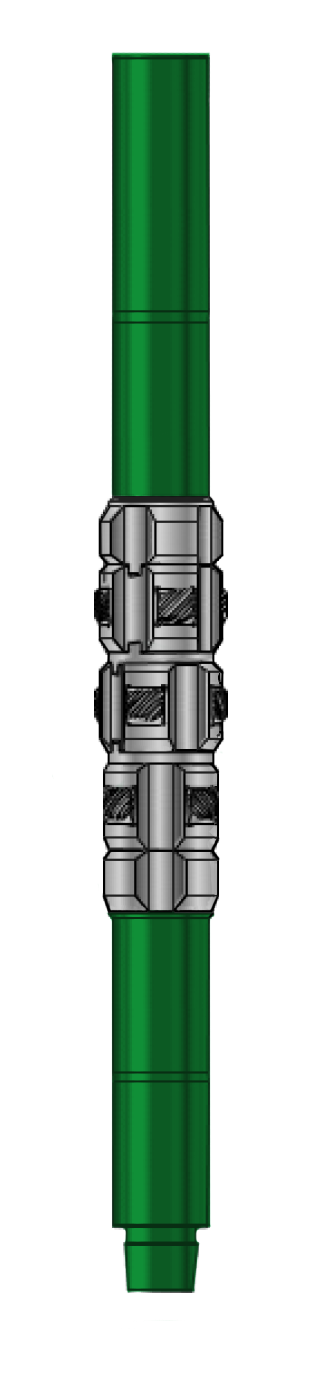

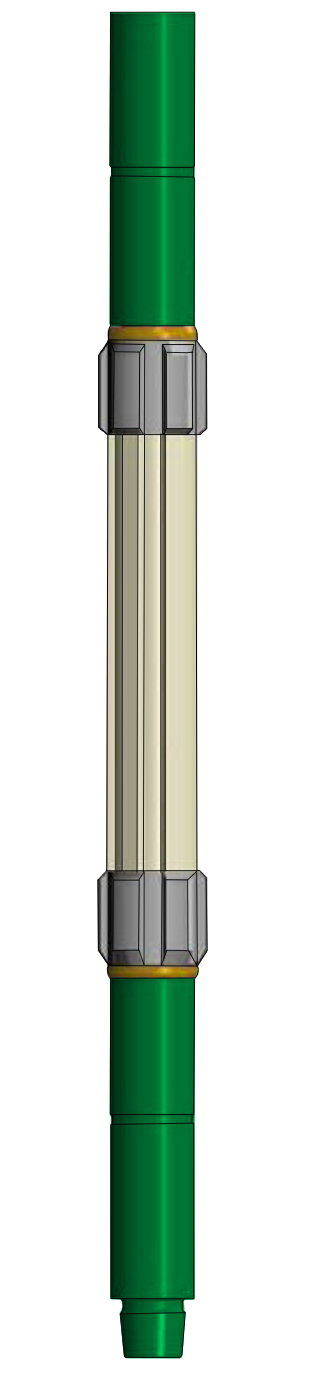

BLADE SCRAPER TOOL

TECSEP’s Blade Scraper Tool is a casing scraper that removes debris from the casing ID. The rotational design of the tool reduces the chance of casing wear and provides 360º scraping coverage, regardless of the well inclination. Angled at 45º, the blades self-clean as the tool is being tripped in hole.

Because of its robust design and large flow area, the Blade Scraper Tool can be incorporated in a clean-up bottom-hole assembly (BHA) even when cement or mechanical barriers are encountered.

PROVIDES 360º SCRAPING COVERAGE APPLICATIONS

APPLICATIONS

- Casing and tubing cleaning operations in vertical and deviated wells

BLADES ANGLED AT 45º

FEATURES AND BENEFITS

- 360º scraping coverage

- Rotational design that reduces the likelihood of casing damage

- Large flow area between the exterior of the tool and the casing ID, which reduces equivalent circulating density (ECD) and guards against surge

- Self-cleaning scraper blades

- Integral centralizers and springs that maintain tool concentricity in a range of casing weights and hole angles

DEBRIS RECOVERY

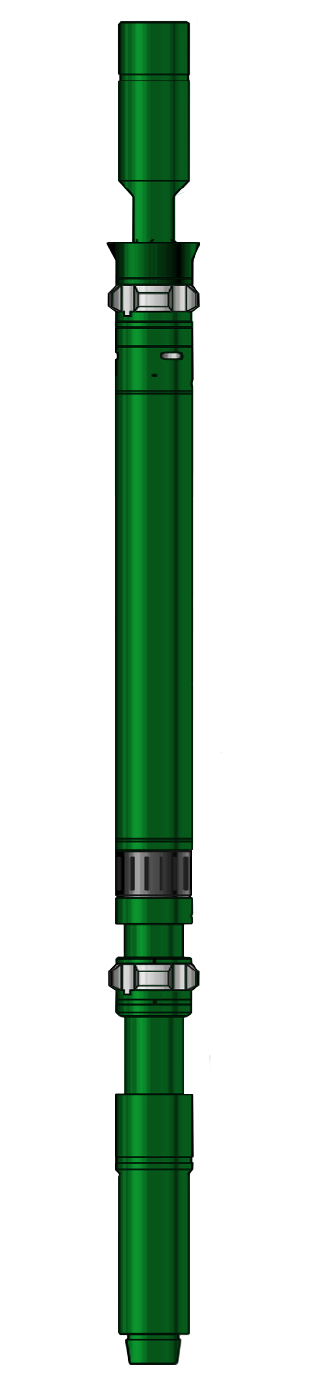

DOWN HOLE FILTER TOOL

TECSEP’s Down Hole Filter Tool is a drillpipe-conveyed, POOH activated downhole filter that removes debris from the wellbore fluids.

It does not require activation via ball or dart. Its unique expanding and retracting wiper cup, provides positive contact between tool OD and the casing ID as the tool is POOH, which enables filtering 100% of the wellbore fluid through the integral system.

All filtered debris is captured inside the solid debris catchment area and can be emptied at surface by loosening a single bolt. Once emptied and inspected, the tool can be re-run, if required.

UNIQUE EXPANDING AND RETRACTING WIPER CUT

APPLICATIONS

- JFiltration of completion fluids

- Debris extraction

ENABLES FILTERING 100% OF THE WELLBORE FLUID

FEATURES AND BENEFITS

- The tool features a one-piece mandrel and has non-rotating centralizers and components

- Outer filtration cup allows a large circulating flow area around the tool and maintains casing ID contact while pulling out of hole (POOH)

- The system is self-activating by POOH. No ball or dart is required

- Internal wire-wrapped screen is protected by a steel skin

- The integral pressure relief system can be set according to well conditions, which prevents swabbing if the tool fills with debris

DEBRIS RECOVERY

DOWN HOLE MAGNET TOOL

TECSEP’s Down Hole Magnet tool is a heavy-duty, bar-type tool used to remove ferrous debris from wellbore fluids.

Down Hole Magnet tool comprises rows of high-strength bar magnets arranged longitudinally along the mandrel of the tool.

The magnet polarities are aligned in such a way that the majority of ferrous debris collects in the valleys between the rows of magnets, thereby maximizing the total flow area around the tool even when it is filled with ferrous debris.

EFFICIENTLY REMORE FERROUS DEBRIS FROM WELLBORE FLUIDS

APPLICATIONS

- Removing ferrous metals during wellbore-cleaning operations

- Capturing and removing cuttings during drilling or milling operations

HIGH-STRENGHT BAR MAGNETS

FEATURES AND BENEFITS

- The Down Hole Magnet tool is rated for use in temperatures up to 300ºF (149ºC)

- High temperature model also available

- Bar magnets are arranged in rows around the mandrel to provide metal-retention forces

- The magnets are triple coated to minimize corrosion issues

- The design enables drill string rotation while the magnet section remains stationary, which reduces casing wear and minimizes the risk of debris becoming detached

CHEMICAL CLEANING

TEC WASH

TECSEP’s Chemical Wash (TEC-Wash) safely removes mud, oil, dirt, and grime from rig-floor surfaces and equipment.

CHEMICAL CLEANING

TEC-VIS

TECSEP’s Viscosifier (TEC-Vis) is a suspension of xanthan gum in an organic solvent gel, it assists in the displacement of fluids, mud, and debris from wellbores.

TECSEP CLEANING SOLUTIONS

APPLICATIONS

- Chemical that assists in cleaning wellbores

- Creation of a spacer pill for completion fluid systems

FEATURES AND BENEFITS

- TEC-Vis enables users to easily create solids-free spacers that improve displacement efficiency and wellbore cleanout

- TEC-Vis can be used in fresh water and a wide range of brines

- TEC-Vis is a liquid-based polymer additive rather than a powder-based additive; therefore, it disperses rapidly without leaving behind clumps of the condensed viscosifying agent in the wellbore.

CHEMICAL CLEANING

TEC-CLEAN

TECSEP’s chemical cleaning (TEC-Clean) is a mixture of non-ionic surfactant in a hydrotreated distillate and glycol solvent.

It is a highly effective aid to displacement. The chemical is used in high-viscosity pills to remove heavy solids from the wellbore before pumping the main clean-up pill.

The chemical remains active across a broad range of temperature environments, from deepwater to high-pressure and high-temperature wells. It is just one offering in a wide portfolio of TECSEP’s wellbore cleaning products developed to meet the requirements of various drilling systems.

TECSEP CLEANING SOLUTIONS

APPLICATIONS

- Wellbore cleaning in a broad range of temperatures

FEATURES AND BENEFITS

- The combined action of the solvents and surfactants in the TEC-Clean chemical releases the solids and mud residue from downhole surfaces and flocculates them, which facilitates removal from the wellbore

- The all-in-one displacement chemical eliminates the need for separate solvent, surfactant, and flocculant products

- TEC-Clean is environmental friendly and is acceptable by OSPAR, a commission that involves 15 governments and the European Union to protect the nearby marine environment.