TECSEP SOLUTIONS

INSPECTION SERVICES

From its inception, TECSEP has been in the business of lifting and non-destructive material testing inspections, which allows us to look back over a treasure-trove of 8 years of experience in the Angolan market. This experience, combined with a high degree of flexibility and highly motivated staff, has characterized us from the beginning.

TECSEP’s Quality Management System ensures that a high standard is maintained in all our services. All our inspectors, both Angolans and Expats are trained and assessed according to our Quality Management System, which incorporates internationally recognized schemes such as IRATA (Rope Access), ASNT, API, and LEEA.

OUR LOCAL CAPABILITIES FOR FIELD INSPECTION SERVICES UTILIZES THE FOLLOWING METHODS:

ELECTROMAGNETIC INSPECTION (EMI)

SPECIAL END AREA (SEA)

DYE PENETRANT (PT)

ULTRASONIC INSPECTION (UT) DRILL STEM ELEMENTS

MAGNETIC PARTICLE INSPECTION (MPI)

THREAD GAUGING

TECSEP SOLUTIONS

INSPECTION SERVICES FULL RANGE

TECSEP offers Drill Pipe and BHA inspections using advanced devices and methods with our expert and experienced staff. Inspection of new and used drill pipe is essential to detecting defects that originate either in manufacturing or during drilling operations.

Drill Pipe Inspection Categories are as mentioned below:

- API RP 7G-2.

- DS1 Category 1-5.

INSPECTION SERVICES

BHA INSPECTION

We can provide BHA inspection services in accordance with the latest API, DS1, Manufacturer and Customer standards.

- Visual Inspection

– Visual Tube Body Inspection

– Visual Connection Inspection

- Dimensional Inspection

- Magnetic Particle inspection – MPI

– Blacklight Connection Inspection

– Magnetic Particle Fluorescent Inspection of Elevator Groove and Slip Recess

– Magnetic Particle Inspection Slip/Upset

– Magnetic Particle Inspection of the Critical Area

– Magnetic Particle Inspection Full Length of Sub’s Having a Section Change

– Magnetic Particle Inspection Full Length of Critical Areas on Kelly

– Magnetic Particle Inspection Full Length of Drive Section - Ultrasonic Inspection

– UT Connection

– UT Slip/Upset - Liquid Penetrant Inspection

- Cleaning

– Cleaning of Slip/Upset Areas with special steel wire brush

– Cleaning of Threads with special steel wire brush - Color Coding and Reporting

INSPECTION SERVICES

CASING AND TUBING

Our multiple inspection techniques provide valuable inspection data where casing or tubing integrity is critical to a wellbore.

Casing is the major structural component of a well. Proper inspections are critical to ensure safe drilling and production programs, and optimization of your casing or tubing strings.

New or used Casing and Tubing inspection services includes:

EMI inspection, API full length drift, visual thread, UT weld inspection, hardness testing, bucking, I.D./O.D. cleaning, thread gauging and dimensional measurements.

INSPECTION SERVICES

RISER

The type of Riser System employed in the Oil & Gas operations offers specific and often critical challenges.

We provide comprehensive services throughout the life cycle of the riser.

We offer a one stop shop to our clients requiring inspection, transportation, maintenance and repair and storage services for marine drilling risers.

TECSEP’s Drilling Risers Services from our facilities in Soyo includes:

- Offshore Inspections

- Transportation Inspections

- Land-based Storage and Preventive Maintenance, including

Full Inspection (Dimensional, Ultrasonic Wall Thickness,

Magnetic Particle - Inspection, Ultrasonic Shear Wave Inspection, Dye Penetrant

Inspection, Visual Inspection) - Disassembly of Risers

- Ultra High Pressure Water Blasting of Risers body and

components prior to painting - Welding repairs and fabrication as necessary

- Removal, Inspection and Replacement of Riser Line Seals

(replacement parts to be provided by client) - Dimensional Inspection of Riser Lines

- Inspection and Replacement of Riser Collars, Thrust Collars and

Plates (replacement parts to be provided by client) - Inspection of Riser Coatings

- Annual, Five-year, and Ten-year Inspections Reassembly

SPECIALITY INSPECTION SERVICES

NON-DESTRUCTIVE TESTING (NDT)

Inspections are critical points in the lifecycle of an asset and are needed to ensure they remain safe and do not become the cause of an avoidable expense.

A scheduled shutdown period to perform intrusive inspections can cause a major disruption to operations.

Well planned and executed NDT delivers valuable data about the condition of the asset and avoids unnecessary stoppages, without compromising safety.

We ensure our inspectors are trained and qualified to the highest local or international standards.

NDT inspection can be performed offshore, in subsea, difficult to access or “at height” locations.

Whatever the location the inspector will be using the most practical and appropriate inspection techniques, to an inspection scheme tailored to the specific area and equipment.

New techniques are continuously being evaluated to establish their value and usefulness to our clients.

SPECIALITY INSPECTION SERVICES

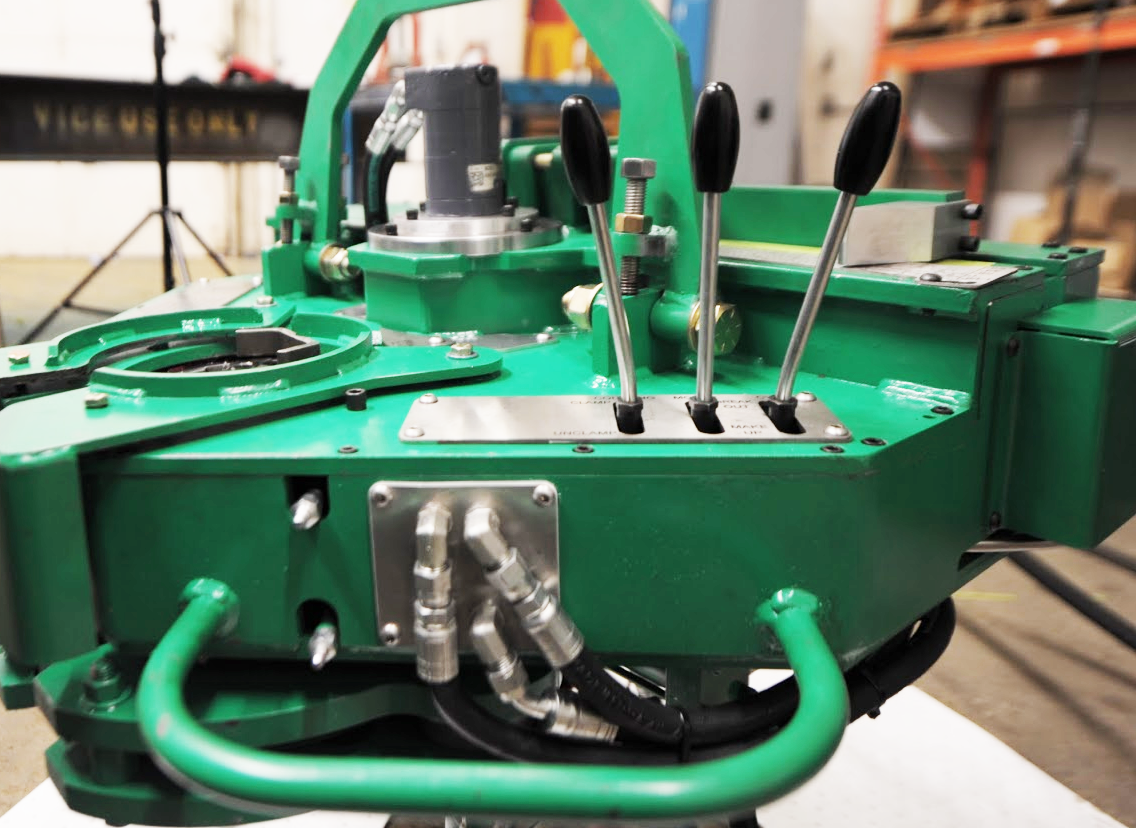

LIFTING EQUIPMENT INSPECTION AND MANAGEMENT SYSTEM

The safety and reliability of a lifting appliance or lifting gear cannot be ensured unless it has received regular inspections.

Regular inspections are particularly important because they provide a useful means of detecting potential hazards which could contribute to accidents.

Regular inspections can also forewarn the owner of necessary preventive maintenance or repair, the lack of which can lead to serious deterioration of the lifting appliance and expensive replacement or repair charges.

An inspection means a visual and physical checking usually supplemented by a functional check to examine the states of individual items of a lifting appliance or lifting gear.

An inspection means a visual and physical checking usually supplemented by a functional check to examine the states of individual items of a lifting appliance or lifting gear.

The purpose of an inspection is to find out whether there is any item having abnormal wear and tear, malfunction, oil leakage, overheating, corrosion, unusual noise, dislocation, visual cracks, misalignment, overloading, abnormal slackening or elongation, and excessive vibration, etc. and if necessary to arrange for subsequent remedial actions such as repair and replacement of the defective parts, or to stop the lifting appliance or lifting gear from further use if a critical condition exists.

A thorough examination should cover those components of lifting appliances and lifting gear which are subjected to certain degree of exposure to wear, deterioration, malfunctioning or misalignment. Lifting appliances and lifting gear should be carefully examined to identify any deficiencies that may constitute a hazard.

To ensure that the lifting appliance or lifting gear is safe to be used, a thorough examination not limited to the following should be conducted:

- Visual examination;

- Dimensional examination;

- Functional or operational test;

- Open-up examination;

- Electrical test and examination;

- Non-destructive test.

At TECSEP we follow the most stringent standards and procedures (DNV, EN and API) for the Inspection of Lifting Equipment and also recommendations and regulations (LOLER, LEEA) to provide the best in quality services to the Angolan Oil Industry. Our lifting equipment Management systems ensure that every single item used in lifting in our client base is captured and managed via our system for Inspection, certification and maintenance to guarantee the safety of these at any time.

SPECIALITY INSPECTION SERVICES

WATER BLASTING

TECSEP’s High-pressure water blasting services is ideally suited for a vast array of applications, ranging from mill scale build-up, paint or sludge removal from reactors, condensers, tanks, evaporators, heat exchangers, boilers, process piping, cyclones, smelt beds, clarifiers and critical operating systems.

Customized tooling allows our trained operators to safely clean where personnel are not permitted.

Covering a broad scope of water-blasting services, TECSEP owns and operates water jetting units and compatible specialist accessories capable of various pressures and flows.

Our units operate from pressures of 1,450 psi to 15,000 psi and, we take pride in tackling the most challenging high-pressure water blasting projects.