TECSEP SOLUTIONS

FILTRATION SERVICES

TECSEP’s Filtration Services is a critical component of the bridge between drilling and completions and is required to optimize the Well-Bore before production, delivering significant savings and improved returns. Our service objective is simple: “To ensure maximum well productivity in a safe, cost effective and timely manner.” Our experienced personnel will be able to support your operations with logistics and safety playing a key role.

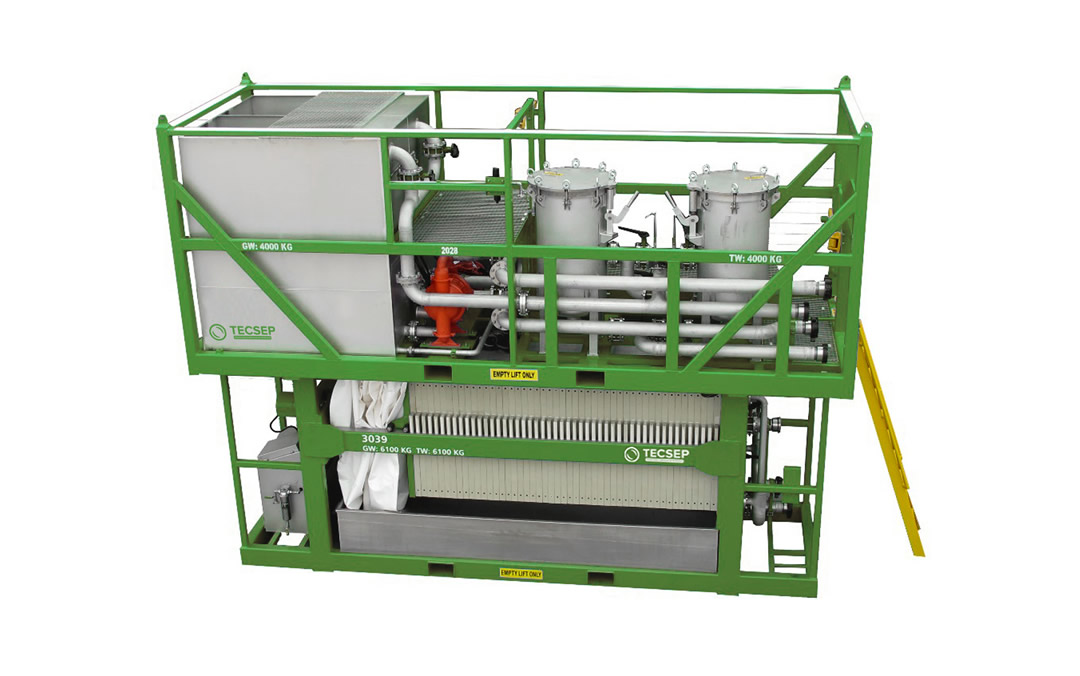

TECSEP delivers customizable filtration options, include stackable filtration units that offer flexibility, safety and performance. Our filtration design packages make the most of rig space by minimizing the filtration footprint without compromising quality or safety.

Our Stackable filter press packages include a slurry tank, a dual pod cartridge unit, and all the auxiliary equipment to conduct efficient, self-contained filtration.

TECSEP’s scope of equipment supply will handle most filtration requirements which includes high pressure, high temperature and aggressive chemical applications.

The oilfield filtration equipment we offer includes:

TECSEP SOLUTIONS

FILTRATION SERVICES FULL RANGE

FILTRATION SERVICES

D.E. FILTER PRESS

Our heavy-duty filter presses for onshore and offshore use, are specially designed for completion, work-over and gravel pack fluids filtration. The presses are complete with a separate slurry skid and all necessary auxiliaries to run an efficient filtration job. The full propylene filter plates are recessed, hence 100% drip free and low NTU readings. TECSEP’s Filter Presses are suitable for light and heavy brines at high flow rates. The Filter Press in combination with a duplex cartridge filter unit, pump unit, our powder and slurry skid are the most reliable and effective filtration set-up for filtration of completion fluids. We can also provide a Dual Filter Press package when required.

TECSEP HEAVY-DUTY FILTER PRESS

APPLICATIONS

- Treating waste while protecting the reservoir from contaminants, including bacteria, scale, clay, rust, etc.

- Specific design for completions, work-over, and gravel-pack fluids filtration.

- Total cleanup of hydrocarbons, emulsions, and dissolved heavy metals.

- Suitability for light- and heavyweight brines.

TECSEP’s Filtration stackable mixing slurry skid is a complete unit for pre-coating, body feed and polishing of fluids. The stackable unit can be placed and fixed on top of the filter press. This set-up will give the minimum footprint during operation of the filter system.The unit has one frame and contains 1 x 15 BBL mixing tanks, air driven pre-coat and body feed pump, two cartridge filter vessels each 50 cartridges. The unit offers a safe working platform and the following benefits:

FILTRATION SERVICES

D.E. SLURRY SKID

To operate a Filter Press you need a Slurry Skid. TECSEP can offer you two options; a single unit or a double unit. The single unit is the most economical option however the double unit offers several features and benefits. The two individual compartments of the double Slurry Skid unit operate separately using one compartment for pre coat and one for dosage. This allows easier operation and switch over and provides the possibility to operate two Filter Presses with one double unit, resulting in minimal down time.

FILTRATION SERVICES

DUPLEX CARTRIDGE FILTRATION UNIT

We provide duplex cartridge filtration units for a wide range of filtration applications, from polishing after diatomaceous earth (DE) filters to hydrocarbon removal. Typically, our duplex cartridge filtration units filter solids between 2 and 20 microns in size. When heavier contamination is expected, the duplex cartridge filtration unit becomes part of an all-inclusive filter press package. Our duplex cartridge filtration unit (TDW 610-50/40) has a high processing volume capacity for numerous applications.

FILTRATION SERVICES

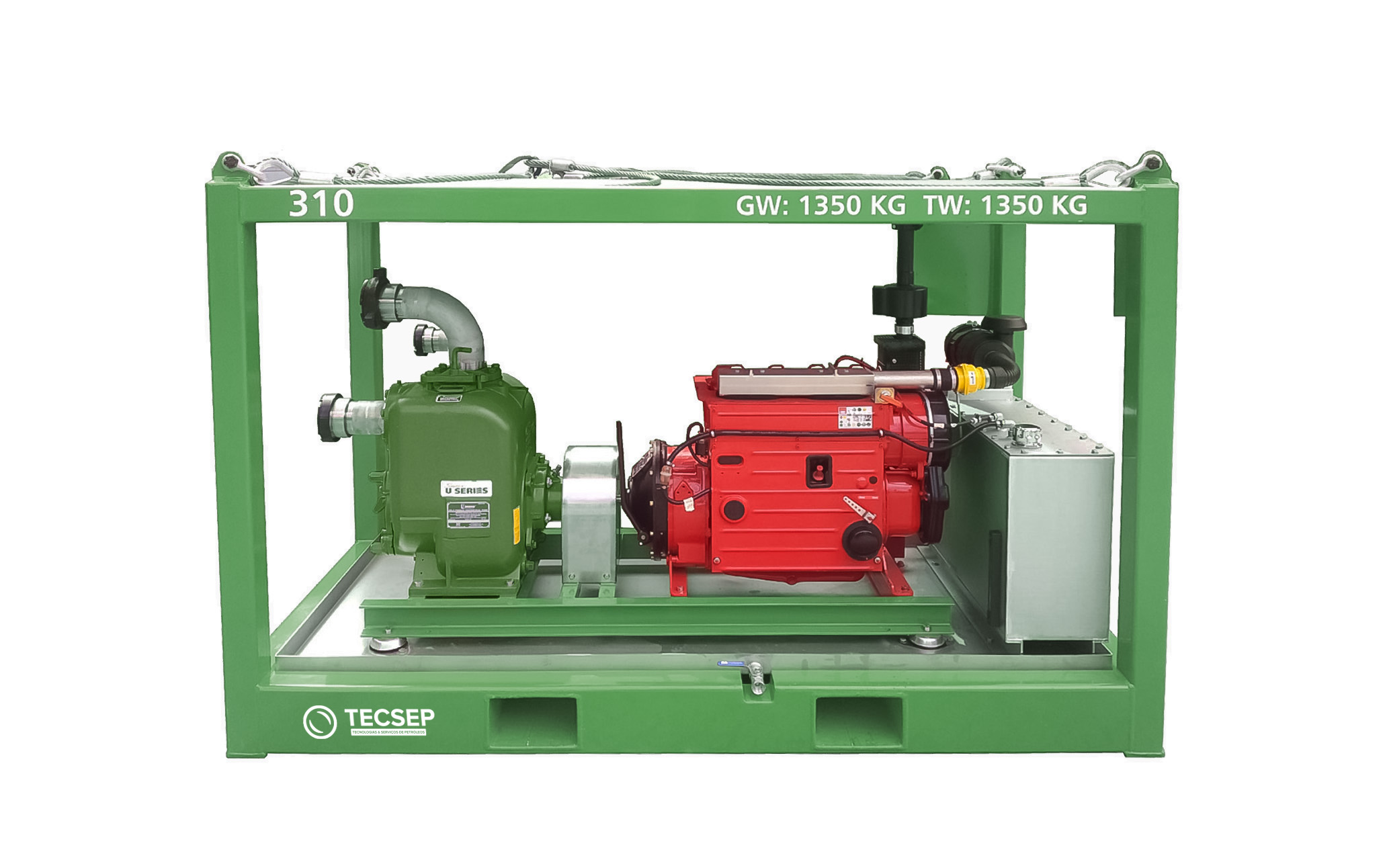

DIESEL CENTRIFUGAL PUMP SKID

TECSEP’s diesel driven pump skid is especially engineered for oilfield applications. The pump can be used as feed pump to our filtration units. Our diesel driven pump is built in an offshore proof DNV certified frame including manual dry clutch, day tank, forklift pockets, lifting slings, drip pan and motor protection guard. The unit is designed for easy and reliable operation and requires minimum maintenance

FILTRATION SERVICES

CARGO BASKET WITH HOSES

TECSEP’s 6.75 x 1.20 x 1.35 m Hose Basket comes with 4-part certified slings and weights 2050 kg. The hose basket is designed for safe transportation of hoses or cargo offshore. The basket has space for up to 40 pieces of 4-inch hoses each 20ft with unions/camlock couplings. The corners of the basket are protected with solid stainless-steel plates to prevent corrosion/damage caused by the heavy coupling on each side of the hose.

FILTRATION SERVICES

FILTRATION CONSUMABLES: FILTER CARTRIDGES

TECSEP offers a wide range of filter cartridges which can be used for different applications.

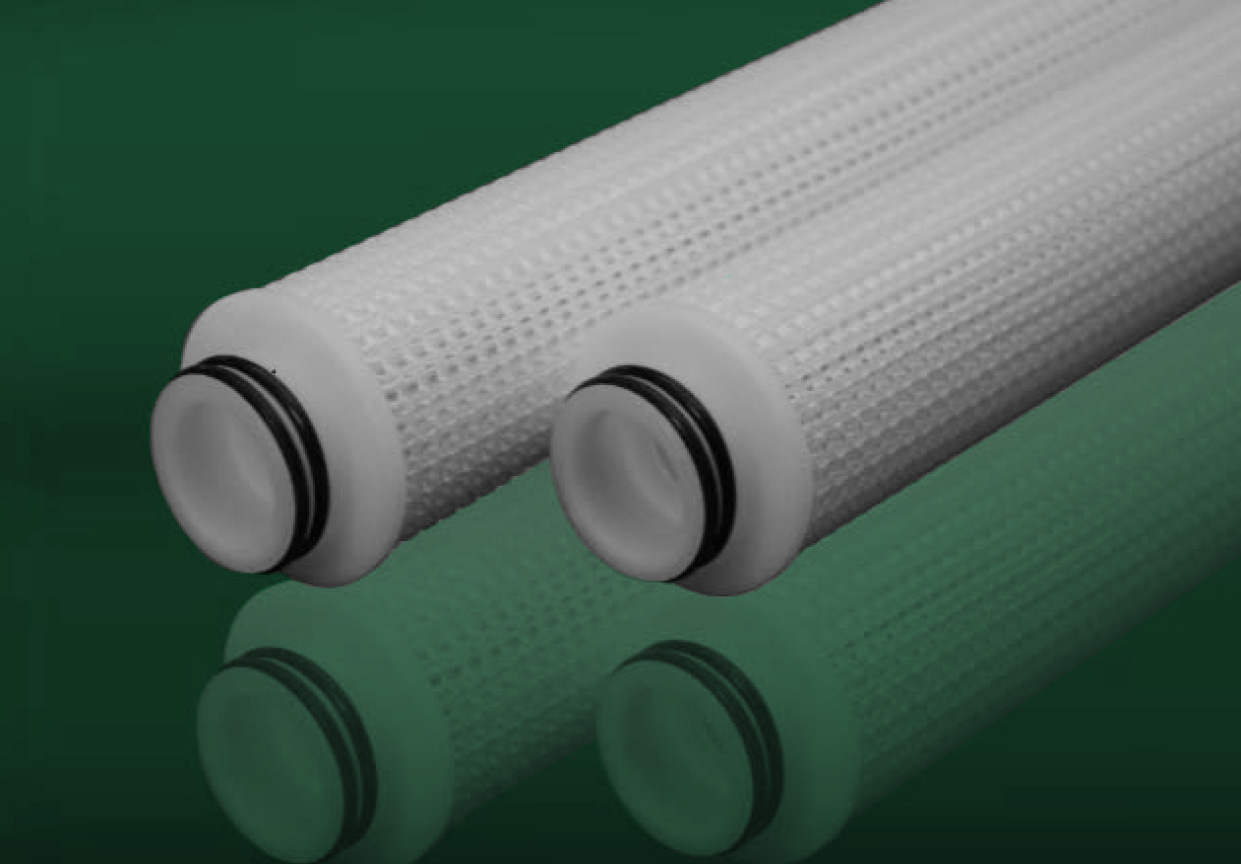

ABSOLUTE RATED FILTERS:

Are used for critical applications requiring fine filtration and guaranteed effluent quality.

EN65 Absolute pleated filter cartridges are manufactured using CNC technology and high-quality materials resulting in a high efficiency filter element that is suited for a wide range of applications.

The filter is a thermally bonded one-piece construction design with rigid outer cage giving superior mechanical strength and integrity.

Absolute filter elements are available in ratings of 0.5 to 50 microns with a Beta ratio of 5000.

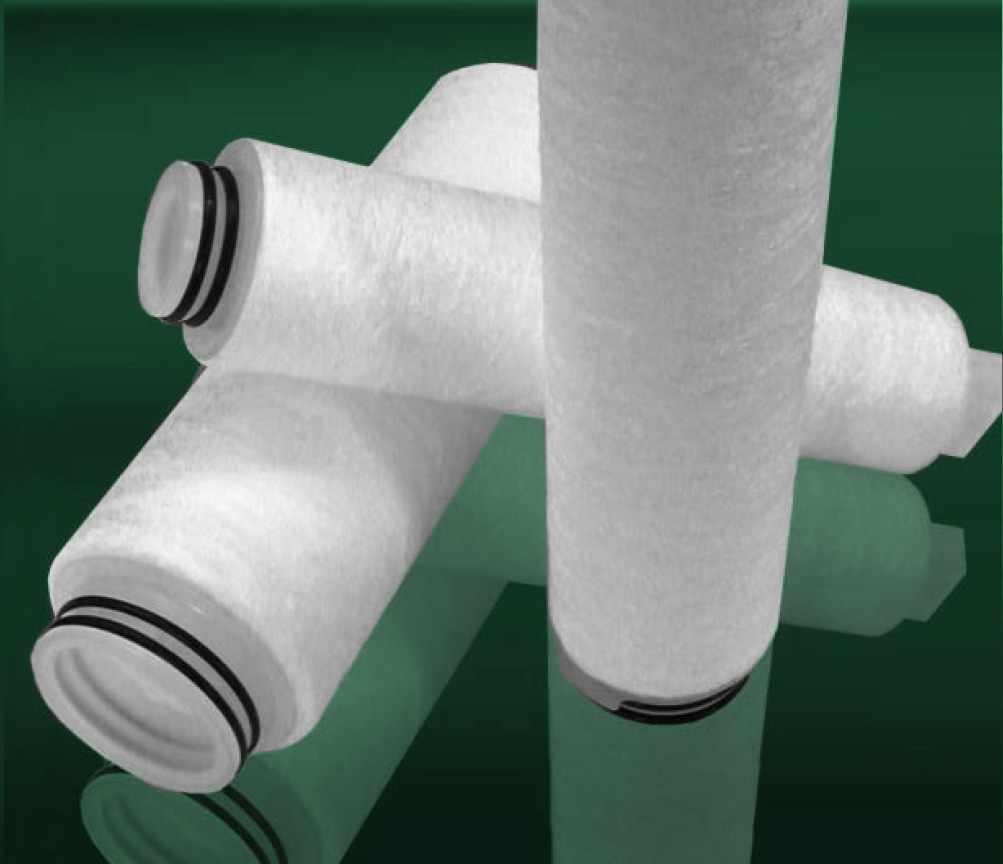

NOMINAL RATED FILTERS:

Are used either as pre-filters before absolute rated elements, or a coarse filter, depending on job requirements.

The EN65 Nominal wound filter cartridge is a thermally bonded extruded media, one-piece core and cap design and has high structural integrity combined with a greater void volume, giving a lower pressure drop, much improved dirt holding capacity and efficiency compared to conventional filters.

OIL ABSORPTION CARTRIDGES:

Many oilfield applications require zero discharge. Therefore, aquick and efficient re¬moval of hydrocarbons from water of brines is required.

The EN65 Oilbond efficiently and economically removes free, emulsified and dissolved oils in many process fluids reclamation and disposal applications.

The oil absorbing filter element has been shown to retain in excess of 99% of trace hydrocarbons in one single pass and will typically hold up to of 1.2 liters of oil per 1m length element.

Oilbond exhibits very low clean pressure loss which gradually increases as the element becomes loaded providing a positive indication of cartridge change out time prior to any oil bypass.

FEATURES

|

|

FILTRATION SERVICES

FILTRATION CONSUMABLES: DIATOMACEOUS EARTH FILTER MEDIA - FILTER AID

DIATOMACEOUS EARTH:

Diatomaceous Earth (D.E.) is used as a filter medium and very suitable for water treatment and completion fluids, but also effective in other liquid filtration processes, such as beer, wine and syrups.

Diatomaceous Earth consists of fossilized remnant of diatoms, algae with distinctive, transparent cell walls made of silicon dioxide.

For good filtration you need a filter aid which is chemically inert and forms a high porosity filter cake to maintain the free flow of the liquid, diatomaceous earth is an excellent filter aid.

We provide Diatomaceous earth (DE) that have all the properties a diatomite needs; high surface area, chemically inert, low density, high porosity, absorptive capacity. The combination of DE filtration in series with 2 microns absolute glass fiber pleated cartridges, will give an optimum performance for filtration of completion fluids.

FILTRATION SERVICES

NTU TURBIDITY METER

TECSEP’s Portable Turbidity Meters offer a high-level performance comparable to laboratory measurements.

Our turbidity meters have a high accuracy in field testing enabling TECSEP’s filtration supervisors to achieve laboratory-grade performance on a wide range of samples, even under difficult, onsite conditions.

These turbidity meters provide direct digital readout in nephelometric turbidity units (NTUs).

FILTRATION SERVICES

TOTAL SUSPENDED SOLIDS KIT

The portable solids analysis kit contains the equipment needed for on-site testing of filtration efficiency by analysis of Total Suspended Solids (TSS).

Gravimetric analysis is utilized to determine the total amount of suspended solids in a completion fluid.

It is common knowledge that fluid containing excessive solids content can cause severe formation plugging through particle invasion.

On -site gravimetric analysis is available utilizing a compact analysis kit.